Robot Packer

Model 600

This robotic pick and place packer offers the benefits of A-B-C’s expertise in product handling and trademark robust construction to deliver gentle handling, precision packing, wide flexibility, and long-term reliability to your packaging line

Robust and Reliable Robot Packing

Pick and place automation is where A-B-C robots shine. Our systems integrate high payload robots with precision servo automation and intuitive controls to deliver simple and reliable operation. We offer a wide range of product orientation and end-of-arm tooling configurations to ensure flexibility and scalability to suit your current and future requirements.

A-B-C’s expertise in product handling combined with proven robotic technology provide optimized solutions for packing a range of product styles:

- Cartons, semi-rigid containers, or flexible packages, bags or cups, bottles or jugs, single or multipacks

- Pack into many case and tray styles including retail ready display

- Pack single or multiple shippers per cycle

- Quick changeover with independent packing modules

- A complete packing solution with line integration options available

Key Features That Benefit Your Production

Intelligent machine control simplifies setup, operations and diagnostics

Operation is simple and repeatable for quick operator proficiency. At the HMI touchscreen, you control all functions, diagnostics, and changeover settings following clear, step-by-step sequences. Real-time operating data is available at a glance.

Perfectly synchronized operation is ensured with non-contact sensors that confirm product and shipper positioning for each operating sequence.

Standard designs offer wide product range and top flexibility

The Model 600 packer offers many standard features to ensure top productivity on your line including high payload robot, servo-powered product feed and case/tray transport, and multiple package transport options to perfectly handle your product type.

This standard design is easily scalable to add more packing options, speeds or product configurations, and custom-engineered designs are also available that provide simple solutions for multiple products or production lines.

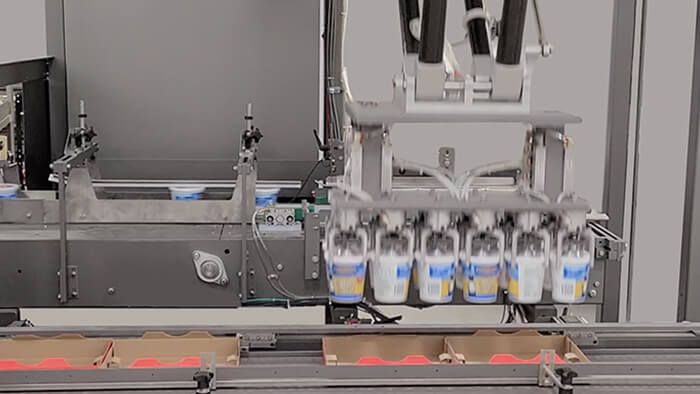

Ultra-gentle and efficient product placement

The 2-axis, servo-operated robotic pick and place packer device provides smooth and harmonious performance during the selection, positioning and packing operation. We employ a variety of mechanical and vacuum end-of-arm tools for different packing tasks, each optimized to ensure complete control of every product from the accumulation conveyor to the shipper.

We analyze each product and design solutions for optimized handling and placement, making simple work of complex tasks.

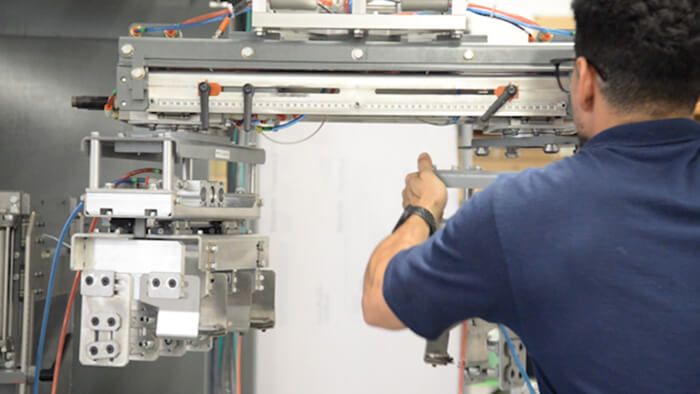

Modular packing heads and one-touch product selection simplify product changes

All product pack configurations are programmed to allow package selection at the operator station. End-of-arm tooling is built into modular units for easy changeout.

Product and case/tray lanes are easily adjusted using slides with locking handles, allowing most changeovers in less than 5 minutes.

Specifications, Standard Features and Options

Standard Features and options

- Codian high payload, 2-axis robot with carbon fiber arms

- Beckhoff servo control of pick and place movement

- Multiple EOAT (End of arm tooling) options available for product handling, determined per product specifications

- Beckhoff IPC with PC-based programming/Ethernet communication

- 12” color touchscreen HMI with on-screen product programming

- Clear, high visibility guards with non-contact safety interlocks

- Heavy gauge plate steel frame

- Elevated beacon fault light

- Grace Port PLC access

Standard Fault Detection Features:

- No case-No load

- No/low air pressure

- Downstream case backup

- Guard door open

- Emergency stop activated

- Motor overload

- Photo eye dirty or misaligned

- Encoder or coupling malfunction

- Individual sensor malfunction

- Fault alarm history record

Options:

- CAT 3 Safety Circuits PL(d) or PL(e)

- Locking guard door switches

- Safety light curtain machine guarding

How Can We Help?

Do you need help finding the best packer for your packaging line?

Our packaging machine specialists are here to assist you in specifying the best packing solutions for your applications, whether you are upgrading from hand packing, replacing an old packer or designing a new secondary packaging line. Our conventional and robot packers suit a wide range of applciations, with many options to customize your packaging equipment to your requirements. Whether your needs are simple or complex, we can help you specify the machines to meet your goals.