A-B-C Blog

Plastics manufacturer reduces liability and improves production with semi-auto palletizing

A-B-C’s customer, an injection molder of closures and small plastics, has developed an innovative stacking method for packing their products into shipping cases that allows up to 30% more product per case. This offers a major benefit for their customers in reduced costs (shipping more product in fewer boxes) and better utilization of warehouse space. However, as a the result, the company is palle…

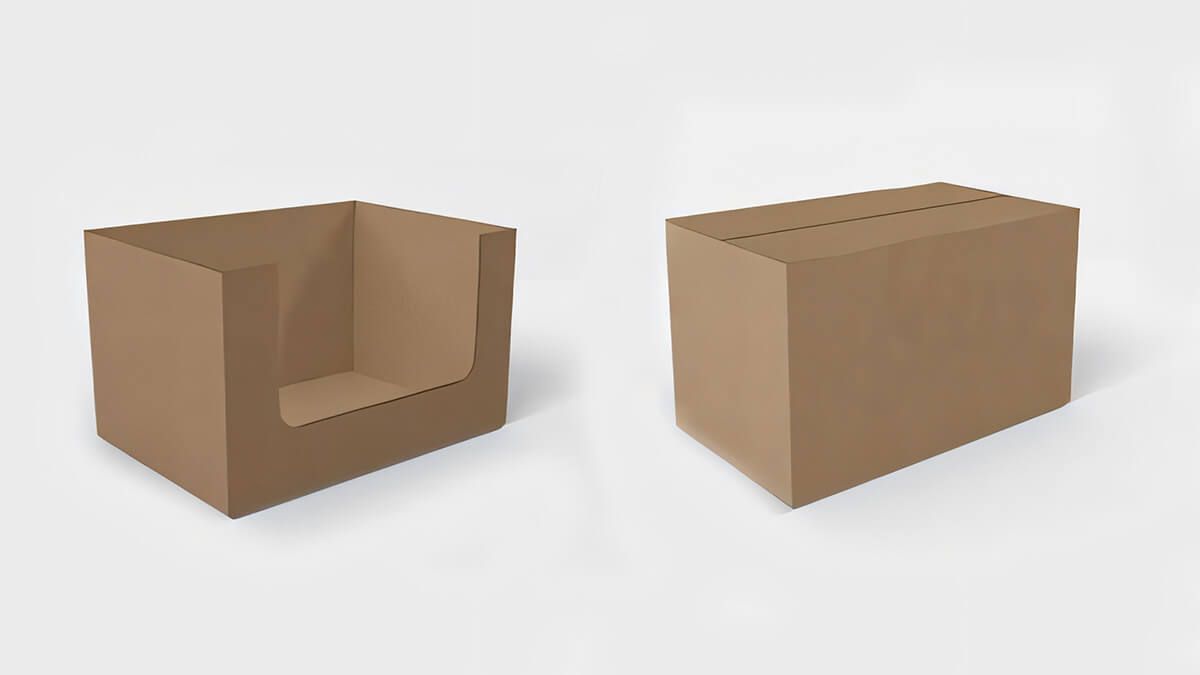

Full height display cases: A retail ready packaging solution

Considering retail ready packaging? Display cases offer a simple and economical solution.

Retail ready packaging (RRP) is on the mind of most packaged goods companies today. In some cases, it is a r…

In the search for sustainable packaging, corrugated is a strong contender

These are tough times for manufacturers, with consumer demands for packaging sustainability and transparency growing louder every day. Challenged to find new solutions, companies are searching for th…

A-B-C case erectors: designed to eliminate jams

You need a case erector that's designed to keep your line running reliably and jam-free. That's why we build A-B-C erectors with exclusive features that overcome the common challenges in case erectin…

3 ways to optimize your palletizing

We offer three efficient solutions to optimize your palletizing process. Explore Low Level palletizing that keeps all operation at floor level, featuring a compact layout, easy access, and energy-eff…

Case Packer Sparkles at Domaine Chandon

Sparkling wine producer Domaine Chandon, Yountville, CA, is reaping big benefits from a new case packer it installed earlier this year. Says Jim Takahashi, manager, purchasing and production qualit…

Purchasing Checklist

The purchase of packaging machinery can affect the efficiency of the entire production line, therefore, care should be exercised in the selection of the vendor and the machinery. As a courtesy to ou…